- Solid State Laser

- Semiconductor Laser

- DPSS laser

- Gas Laser

- Fiber Laser

- Fiber Coupled Laser(MM)

- Fiber Coupled Laser(SM)

- Ultrafast laser

- Femtosecond Laser

- Picosecond Laser

- Pulsed Laser

- Q-switched Laser

- Raman Laser

- Narrow Linewidth Fiber Laser

- Wavelength Tunable Laser

- Laser Diode

- Laser Module

- Pigtailed Laser

- DFB Laser

- DBR Laser

- SLED Laser

- VCSEL Laser

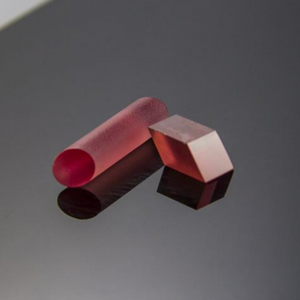

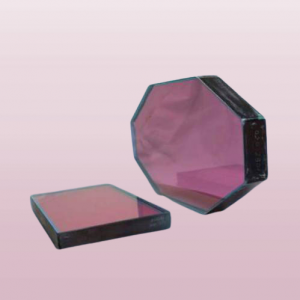

Erbium Glass(Er,Cr,Yb: Glass) – Laser Crystal – Gain Medium – Customized Products

Product ID: 6583

$100

Erbium Glass(Er,Cr,Yb: Glass) – Laser Crystal – Gain Medium – Customized Products

Erbium Glass doped with Er3+, Yb3+ and Cr3+, Erbium-doped glass laser provides a useful coherent source in the spectral range near 1.5 μm, which is relatively safe for the human eye and is convenient in many applications, such as lidar and range measurements, fiber-optic communication, and laser surgery. In spite of the considerable progress in the development of InGaAs laser diode pump sources, Xe flashlamp will continue to be used as pump sources of Er: glass lasers because of their high reliability and low cost, and also the simplicity of design of such systems. Since about half the flashlamp radiation energy is emitted in the visible and near infrared (IR) ranges, a second sensitizer Cr3+ is introduced into Yb-Er laser glasses to utilize this energy.

Note:

$100 is a deposit, not the final price of the product. Please contact us for price if needed.

Features:

High laser efficiency

Low laser threshold

Safe for human eye

High light conversion

Material Specifications

| Materials | Cr14 | CrE5 |

| Orientation | [100] or [110]±0.5° | [100] or [110]±0.5° |

| Mass Density | 3.10 g/cm3 | 2.95 g/cm3 |

| Mohs Hardness | 8.5 | 8.5 |

| Young’s Modulus | 57.6 GPa | 57.6 GPa |

| Strength of Extension | 2 GPa | 2 GPa |

| Melting Point | 1970°C | 1970°C |

| Thermal Conductivity | 0.7 | 0.8 |

| Specific Heat Capacity/(J·g-1·K-1) | 0.59 | 0.59 |

| Thermal Shock Resistance Parameters | 800 W/m | 800 W/m |

| Thermal Coefficient Optical path length(10-7 /ºC)(20〜100ºC) | 3.6 | |

| Linear Thermal Expansion Coefficient(10-7 / K)(20〜100℃) | 103 | 80.5 |

| Linear Thermal Expansion Coefficient(10-7 / K)(100〜300℃) | 127 | 87 |

| Softening Temperature(℃) | 493 | 519 |

| Transformation Temperature(℃) | 455 | 476 |

| Chemical Durability (weight loss in 100 C distilled water)(μg/ hr.cm2) | 103 | |

| dn / dT(10-6 /ºC)(20〜100ºC) | -5.2 | -6.8 |

| Refractive Index @ 1535 nm | 1.53 | 1.533 |

| Refractive Index @ 589.3nm) | 1.539 | 1.541 |

| Abbe Value | 64 | 63.6 |

Optical Properties

| Optical Density | 0.1 to 0.8 |

| Fluorescent Lifetime | 7.7-8.2 ms |

| Concentration | 0.5 mol % ~ 3 mol % |

| Emission Wavelength | 1535 nm |

| Absorption Coefficient | 1.0 cm-1 ~ 7 cm-1 |

| Emission Absorption Cross Section | 0.75×10-20cm2@1535nm |

| Transmittance | 10% to 90% |

| Coating | AR≤ 0.2% @1535nm |

| Damage Threshold | > 500 MW / cm2 |

Polishing Specifications

| Orientation Tolerance | < 0.5° |

| Thickness/Diameter Tolerance | ±0.05 mm |

| Flatness | <λ/8@632 nm |

| Wavefront Distortion | <λ/4@632 nm |

| Surface Finish | 10-5(MIL-O-13830A) |

| Parallelism | 10〞 |

| Perpendicularity | 15ˊ |

| Clear Aperture | >90% |

| Chamfer | <0.1×45° |

| Max. Size | dia (3-12.7)×(3-150)mm2 |

.jpg)