- Solid State Laser

- Semiconductor Laser

- DPSS laser

- Gas Laser

- Fiber Laser

- Fiber Coupled Laser(MM)

- Fiber Coupled Laser(SM)

- Ultrafast laser

- Femtosecond Laser

- Picosecond Laser

- Pulsed Laser

- Q-switched Laser

- Raman Laser

- Narrow Linewidth Fiber Laser

- Wavelength Tunable Laser

- Laser Diode

- Laser Module

- Pigtailed Laser

- DFB Laser

- DBR Laser

- SLED Laser

- VCSEL Laser

YLF+Nd:YLF+YLF – Laser Crystal – Bonding Crystal – Customized Products

Product ID: 6758

$100

YLF+Nd:YLF+YLF – Laser Crystal – Bonding Crystal – Customized Products

YLF+Nd: YLF+YLF bonding crystal is a bonding crystal formed by bonding pure YLF at both ends of Nd: YLF, which can effectively improve the comprehensive performance of Nd: YLF laser.

The thermal conductivity of Nd: YLF is 0, 06 w/cm/ ° k@ 25 ° C, and the thermal conductivity of pure YLF crystal is 14w/m/ K@20 ℃ 10.5W/m/ K@100 ℃, both ends are bonded to form YLF+Nd: YLF+YLF bonded crystal, which can effectively improve the thermal effect of Nd:YAG crystal, reduce the thermal lens effect formed during laser pumping, improve the beam quality of laser, improve the output efficiency of 1047nm and 1053nm laser, improve the stability of laser output capacity, and improve the service life of laser.

TaorLab uses surface activation bonding technology, which is a bonding technology at low or normal temperature. The typical features are surface cleaning and surface activation. Before bonding, the bombardment of fast atoms or ion beams on the bonding surface can effectively increase the bonding strength and achieve high-quality bonding between inorganic materials, metals and semiconductor materials. Compared with the high-temperature thermal bonding method, the surface activation bonding technology has higher bonding force interface, better optical absorption loss and surface shape change control, while the impurities on the thermal diffusion bonding surface cannot be removed and are bonded on the bonding surface. Surface activated bonding technology has the advantages of removing various polishing residual components, removing organic pollutants, removing surface oxide layer, breaking chemical bonds of materials, and improving activation energy.

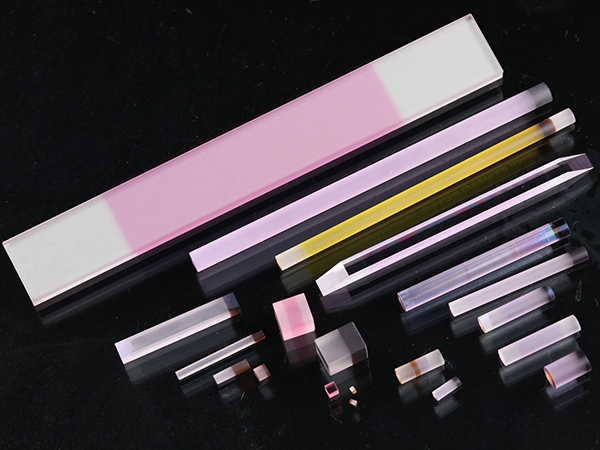

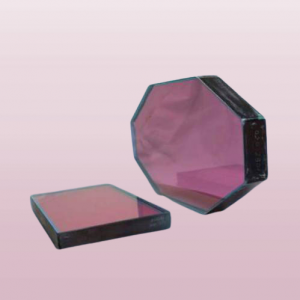

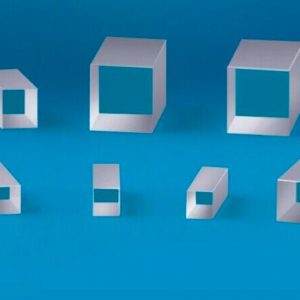

The produced YLF+Nd:YLF+YLF bonded crystals have high bonding strength, small bonding surface absorption loss (generally less than 20ppm) and small change of bonding surface shape (bonding surface shape <lamda/8). The shape of the bonded crystal can be rod, plate, waveguide or sandwich. Various types of coatings can be provided at both ends of the bonded crystal, such as two end antireflection films AR@1040 ~ 1060nm, or s1: HR@1047 /1053nm,S2: PR@1047 /1053nm, etc.YLF+Nd:YLF+YLF bonded crystals are widely used in the fields of mode-locked laser, continuous laser and material processing.

Note:

$100 is a deposit, not the final price of the product. Please contact us for price if needed.

FEATURES

It can effectively improve the thermal effect of nd:yag crystal

Reduce the thermal lens effect formed during laser pumping

Improve the beam quality of laser, and improve the output efficiency of 1047nm and 1053nm laser

It can improve the stability of the output capacity of the laser and the service life of the laser

YLF+Nd:YLF+YLF

| YLF+Nd:YLF+YLF | |||

| Materials | YLF | Nd:YLF | YLF |

| Concentrations | / | 0.1~3% | / |

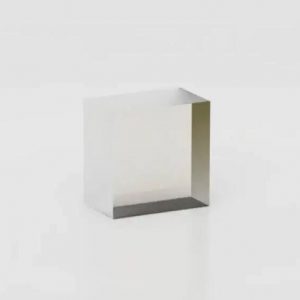

| Structure | Rods/Slabs/Sandwich/Waveguide/ | ||

| End-face Configuration | Flat/Convex/Wedge | ||

| Side Configuration | Polish/Fine Ground | ||

| Coating available | AR@1040~1060nm | / | AR@1040~1060nm |

| HR@1047/1053nm | / | PR@1047/1053nm | |

| others | / | others | |