- Solid State Laser

- Semiconductor Laser

- DPSS laser

- Gas Laser

- Fiber Laser

- Fiber Coupled Laser(MM)

- Fiber Coupled Laser(SM)

- Ultrafast laser

- Femtosecond Laser

- Picosecond Laser

- Pulsed Laser

- Q-switched Laser

- Raman Laser

- Narrow Linewidth Fiber Laser

- Wavelength Tunable Laser

- Laser Diode

- Laser Module

- Pigtailed Laser

- DFB Laser

- DBR Laser

- SLED Laser

- VCSEL Laser

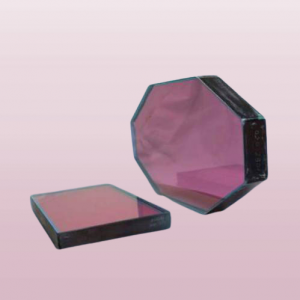

Cr:YAG(Chromium-doped yttrium aluminum garnet) – Passively Q-switched Crystal – Customized Products

Product ID: 6647

$100

Cr:YAG(Chromium-doped yttrium aluminum garnet) – Passively Q-switched Crystal – Customized Products

Cr:YAG crystal, also known as chromium-doped yttrium aluminum garnet crystal, with the chemical formula of Cr: Y3Al5O12. It is a relatively excellent Q-switched crystal product.

It can be used not only as a Q-switch, but also as a gain medium because of its excellent physical and chemical properties. It is widely used in the field of passively Q-switched lasers of laser rangefinders, lidar and LIBS systems.

Cr: YAG has the advantages of chemical stability, durability, UV resistance, good thermal conductivity, great damage threshold (>500 mw/cm2) and simple operation. It is surpassing traditional materials such as LIF and organic dyes.

Cr: YAG is an excellent and widely used electro-optical material for passive Q-switched (laser diode or lamp pumped) Nd: YAG, Nd: YLF, Nd: YVO4 and other 0.8~1.2 μm Nd (or Yb) doped lasers. It is also an active medium for CW, pulse or self-mode-locked tunable NIR solid-state lasers. The tunable range is 1340 – 1580 nm and the working wavelength is 950-1100 nm.

The absorption saturation at 1060 nm band can be used in small Nd: YAG oscillators with flashlamp or laser diode pump, instead of dye or lif:f central passive Q-switch, so that Cr4+: YAG crystal can achieve self mode locking (KML) state. It provides an opportunity to build a laser source with a pulse duration shorter than 100 fs at 1450-1580 nm.

Note:

$100 is a deposit, not the final price of the product. Please contact us for price if needed.

Features of Cr: YAG Crystal

Radiation stability

High thermal conductivity

High damage threshold (> 500 MW/cm2)

Excellent physical and chemical properties

Physical and Chemical Properties

| Attribute | Numerical |

| Chemical Formula | Cr4+:Y3Al5O12 |

| Crystal Structure | cubic – la3d |

| Lattice Constant Å | 12.01 |

| Orientation | [100] or [110] < ±0.5° |

| Mass Density | 4.56 g/cm3 |

| Mohs Hardness | 8.5 |

| Young’s Modulus | 335 GPa |

| Tensile Strength | 2 GPa |

| Melting Point | 1970°C |

| Thermal Conductivity | 0.1213 |

| Specific Heat/(J·g-1·K-1) | 0.59 |

| Thermal Expansion/(10-6 /°C @ 25°C) | 7.8 <111> |

| 7.7 <110> | |

| 8.2 <100> | |

| Thermal Shock Resistance Parameters | 800 W/m |

| Extinction Ratio | 25dB |

| Poisson Ratio | 0.25 |

| Refractive Index @ 1064 nm | 1.83 |

| Charge Compensated Ion | Ca2+, Mg2+ |

Optical Properties

| Attribute | Numerical |

| Optical Density | 0.1 to 0.8 |

| Fluorescence Lifetime | 3.4μs |

| Concentration | 0.5 mol % ~ 3 mol % |

| Emission Wavelength | 1350 nm ~ 1600 nm |

| Absorption Coefficient | 1.0 cm-1~ 7 cm-1 |

| Ground State Absorption Cross-section | 4.3×10-18 cm2 |

| Emission Absorption Cross-section | 8.2×10-19 cm2 |

| Transmission | 10% to 90% |

| Coating | AR≤ 0.2% @1064nm |

| Damage Threshold | > 500 MW / cm2 |

Polishing

| Attribute | Numerical |

| Orientation Tolerance | < 0.5° |

| Thickness/Diameter Tolerance | ±0.05 mm |

| Surface Flatness | <λ/8@632 nm |

| Wavefront Distortion | <λ/4@632 nm |

| Surface Quality | 5-Oct |

| Parallelism | 10〞 |

| Perpendicularity | 5ˊ |

| Clear Aperture | >90% |

| Chamfer | <0.1×45° |

| HR Coating | <= 0.2% (@ 1340nm) |

| Biggest Size | 2*2-15*15 mm×20mm |

.jpg)