Acousto-optic Modulator for High-power Pulsed Fiber Laser 786

Acousto-optic Modulator for High-power Pulsed Fiber Laser

Abstract:

The present invention relates to an acousto-optic modulator for high-power pulsed fiber lasers, including an input pigtail, a collimating lens, an acousto-optic device, a focusing lens, and an output pigtail. The input pigtail is placed at 3.7° with the horizontal plane, and the output tail The fiber and the horizontal plane are placed at 0° or 3.7°, the input pigtail and collimating lens are installed together to form an input fiber collimator, and the output pigtail and focusing lens are installed together to form an output fiber collimator, and then the input, The output fiber collimator and the acousto-optic device are assembled as a whole; a narrowband filter can be placed between the acousto-optic device and the output fiber collimator, and the input fiber collimator and output fiber collimator can be combined into one Fiber collimator, add a narrow band high reflector. The invention effectively improves the mechanical stability of the laser system, can effectively suppress the nonlinear effect in the doped fiber, and realizes high-power, narrow-spectrum pulsed laser output by coating different components.

Background technology

Q-switched double-clad fiber lasers have many advantages such as low price, compact structure, high efficiency, narrow line width, tunable wavelength, etc., in many fields such as remote sensing, ranging, medical, military, industrial processing, nonlinear optical applications, etc. Widely used.

At present, the commonly used method to obtain high-power pulses through double-clad fiber is that the main oscillator provides a “seed” pulse, and then injects it into the double-clad fiber amplification (M0PA) to obtain it. The seed oscillator (M0) often uses a mode-locked laser or Traditional Q-switched solid-state lasers [see Prior Art: CLE02002, CThX3, 591]. A simpler method is to insert a Q-switched device directly into the double-clad fiber laser cavity to obtain high peak power and high energy lasers. Pulse [see Prior Art: CLE02003,626]. Although the above two methods can obtain high-power pulsed laser output, it is not easy to realize the full fiber laser of the laser.

In order to realize the full fiberization of the fiber laser, one method is to use a modulated semiconductor laser as the M0 in the M0PA structure, that is, a multi-stage fiber amplification structure [see Prior Art: Opt. Lett., 30 (24), 2005, P3299] . The disadvantage of this method is that the output power of the seed source is small, and multi-stage amplification is required to achieve the required power, and an optical isolator is required before each stage of amplification, which easily produces nonlinear effects in the fiber, which limits its output power. The further increase, and the cost is higher. Another method is to insert a pigtailed Q-switched device into the double-clad fiber laser cavity. This method also realizes the full fiberization of the laser, making the laser more compact, but it is easy to carry at high power. The new problem of self-excited oscillation in the cavity also limits the further increase of laser power.

The purpose of the present invention is to overcome the above-mentioned problems in the prior art and provide an acousto-optic modulator for high-power pulsed fiber lasers. The acousto-optic modulator of the present invention has pigtail input and output, which can easily realize the All fiber optic. Corresponding treatment of the end face of the pigtail can suppress the self-excited oscillation in the doped fiber, so as to achieve high-power pulsed laser output, and achieve narrow-spectrum laser output by coating different components.

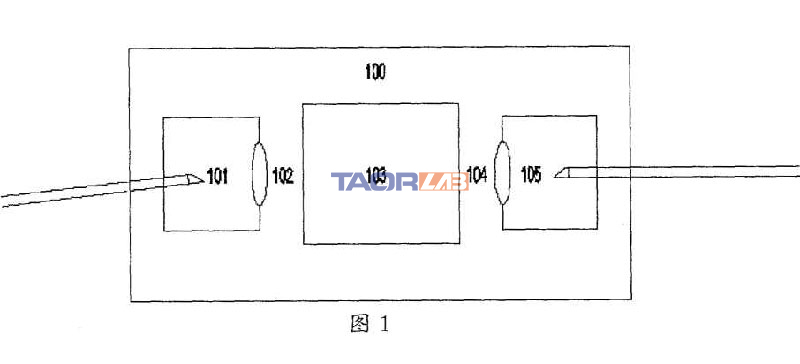

The structure of the acousto-optic modulator for high-power pulsed fiber lasers of the present invention is shown in Figure 1, Figure 2 and Figure 3.

Acousto-optic modulator for high-power pulsed light, including input pigtail 101, collimating lens 102, acousto-optic device 103, focusing lens 104 and output pigtail 105. Input pigtail 101 is placed at 3.7° with the horizontal plane, and output The pigtail 105 is placed at 0° to the horizontal plane, the input pigtail 101 and the collimating lens 102 are installed together to form an input fiber collimator, and the output pigtail 105 and focusing lens 104 are installed together to form an output fiber collimator, and then the input The fiber collimator, the output fiber collimator, and the acousto-optic device 103 are assembled as a whole 100. The input pigtail 101 and the output pigtail 105 are fused with fiber end caps and each ground into an oblique 8° plane, and A broadband antireflection film is plated on the oblique 8° plane of the input pigtail 101, and a narrowband transmission film is plated on the oblique 8° plane of the output pigtail 105. As shown in Figure 1.

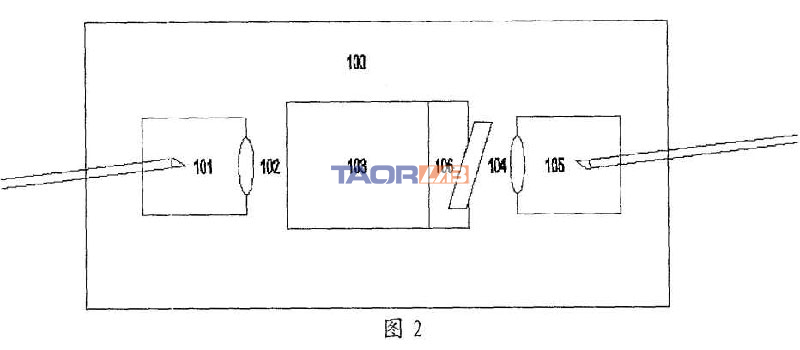

The acousto-optic modulator of another structure of the present invention is shown in Fig. 2. The input pigtail 101 is placed at 3.7° with the horizontal plane. The input pigtail 101 and the collimating lens 102 are installed together to form the input fiber collimator. The ends of the fiber 101 are fused with fiber end caps and each ground into an oblique 8° plane, and a broadband anti-reflection coating is plated on the oblique 8° plane. The output fiber formed by the acousto-optic device 103, the output pigtail 105 and the focusing lens 104 is collimated A narrow-band filter 106 is placed between the devices, and the output pigtail 105 is placed at 3.7° from the horizontal plane. A broadband anti-reflection coating is plated on the oblique 8° plane of the output pigtail 105. The acousto-optic device 103 and the narrow-band filter 106 are installed together. , And the narrow-band filter 106 and the first-order diffraction direction of the acousto-optic device 103 are placed at a corresponding angle, so that the narrow-band filter 106 has the maximum transmittance to the set wavelength, and cannot reflect other wavelengths of light back to the acousto-optic The device 103 enters the input fiber collimator, and then the input fiber collimator, the output fiber collimator and the acousto-optic device 103 and the narrowband filter 106 are assembled as a whole 100.

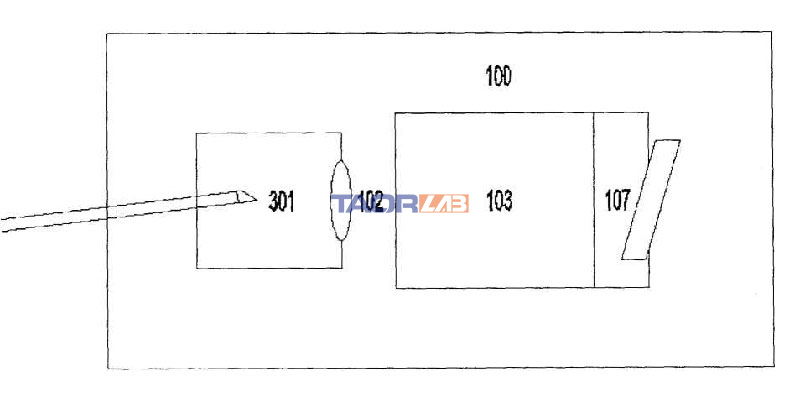

Another structure of the acousto-optic modulator of the present invention is shown in Figure 3. The input pigtail and output pigtail are combined into a pigtail 301, the focusing lens 104 is removed, and a narrow-band high reflector 107 is added. The pigtail 301 is connected to the horizontal plane. Place it at 3.7° and install it with the collimating lens 102 to form a fiber collimator. The end of the pigtail 301 is fused with a fiber end cap and ground to an 8° bevel, and the bevel is plated with a broadband antireflection coating, acousto-optic device 103 And the narrow-band high-reflective mirror 107 are installed together, and the narrow-band high-reflective mirror 107 is perpendicular to the first-order diffracted light through the acousto-optic device 103, and then the two parts are assembled into a whole 100.

The three acousto-optic modulators of the present invention are free of internal adjustment, which greatly improves the mechanical stability of the entire system.

The 1064±0.5nm anti-reflection coating is plated on the 8-degree oblique surface of the output pigtail 105. Only for Yb-doped fiber lasers, the anti-reflection coating of the corresponding wavelength can be selected according to the working wavelength of the doped fiber. The anti-reflection coating is highly transparent to the 1064+0.5nm laser, ensuring that the laser of this wavelength forms an oscillating output in the cavity, and the light of the other wavelengths obliquely has a large reflection loss, thereby narrowing the width of the laser output spectrum.

The narrow-band filter 106 is placed at an angle with the acousto-optic modulator 103, and the surface is coated with a narrow-band transmission film. The narrow-band transmission film of the corresponding wavelength can be selected according to the working wavelength of the gain fiber. For example, the Yb-doped fiber laser is coated with 1064± The 0.5nm narrow-band transmission film ensures that the laser with the set wavelength will form an oscillating output in the cavity, while obliquely facing the light of the other wavelengths has a large reflection loss, thereby narrowing the width of the laser output spectrum.

The surface of the narrow-band high reflection mirror 107 is coated with a narrow-band high-reflection film. The narrow-band high-reflection film of the corresponding wavelength can be selected according to the working wavelength of the gain fiber. For example, for a Yb-doped fiber laser, a 1064+0.5nm narrow-band high-reflection film is coated , Placed perpendicular to the first-order diffraction direction of the acousto-optic device, to ensure that the laser of the set wavelength forms an oscillating output in the cavity, and the light of the other wavelengths has a large transmission loss, thereby narrowing the width of the laser output spectrum.

The invention is an acousto-optic modulator with pigtail input and output, easy to realize all-fiber fiber laser, which effectively improves the mechanical stability of the laser system, can effectively suppress the nonlinear effect in the doped fiber, and can be used in different components The method of coating film to achieve high-power, narrow-spectrum pulsed laser output.

Specific implementation

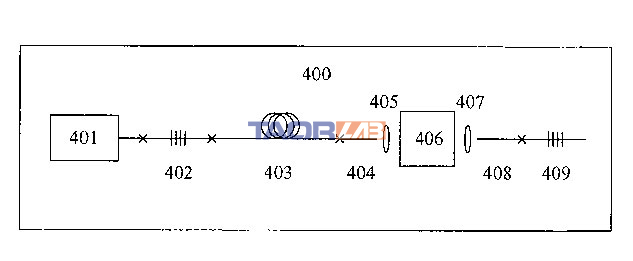

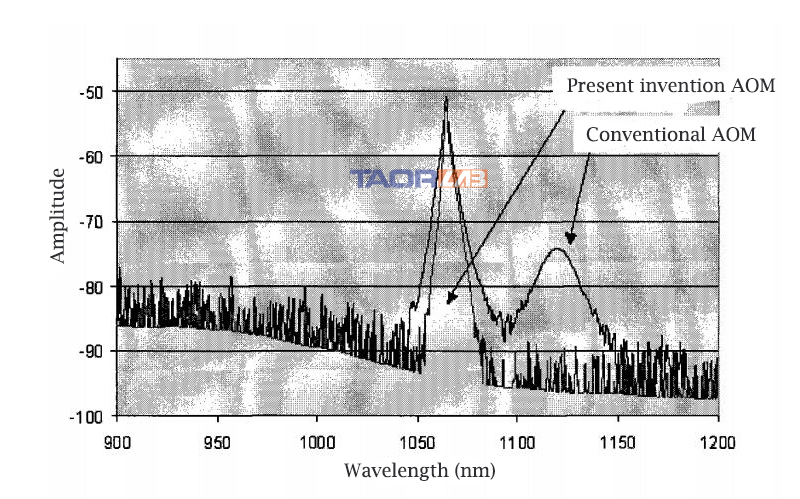

As shown in Figure 4, the pigtailed 915nm pumped semiconductor laser 401 is fused to the total reflection fiber grating 402, the total reflection fiber grating is fused to the gain fiber 403, the gain fiber is fused to the input pigtail 404, and the input pigtail is fused to the fiber end The cap is ground into an 8° inclined surface, then a broadband antireflection coating is plated, and it is placed at 3.7° from the horizontal. The laser generated by the gain fiber passes through the input pigtail 404 and the collimating lens 405 to form a collimated beam into the acousto-optic The device 406 generates Bragg diffraction, and the diffracted first-order light is coupled into the pigtail 408 through the focusing lens 407. The output pigtail 408 is fused with a fiber end cap, ground into an 8° bevel, coated with a narrow-band anti-reflection coating, and placed at 0° from the horizontal plane. In this way, only the narrowband wavelength set in the first-order diffracted light is allowed to enter the output pigtail 408, while reflecting other wavelengths, the reflected other wavelengths will not enter the output pigtail through the acousto-optic device, and the output pigtail 408 and part of the The reflective fiber grating 409 is spliced. In this way, the fiber gratings 402 and 409 form a resonant cavity. Because the output pigtail 408 and the oblique 8° surface are coated with a narrow-band anti-reflection coating, the excitation of other wavelengths is suppressed, so that the pulse fiber laser formed in this way has a narrow linewidth output. No nonlinear wavelengths appear. We use this structure to obtain an average output power of 2W at a frequency of 20kHz, a pulse width of 40ns, and a peak power of 2.5kW. Fig. 5 shows the output spectrum of the acousto-optic modulator using the present invention, and comparing it with the spectrum of the same power level generated by the ordinary acousto-optic modulator, it is obvious that the spectrum is broad and has Raman wavelengths.

Figure 4: A schematic diagram of a specific embodiment of the present invention.

Figure 5: A graph showing whether to use the output spectrum of the acousto-optic modulator of the present invention and comparing the spectrum with the same power level generated by a common acousto-optic modulator.

oaiuBOcXdbm

AgivWtFc

cyDTShioKtxRgflm

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://www.binance.com/ES_la/register?ref=T7KCZASX

Your article helped me a lot, is there any more related content? Thanks!

Your article helped me a lot, is there any more related content? Thanks!

Your enticle helped me a lot, is there any more related content? Thanks!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Keep up the fantastic work! Kalorifer Sobası odun, kömür, pelet gibi yakıtlarla çalışan ve ısıtma işlevi gören bir soba türüdür. Kalorifer Sobası içindeki yakıtın yanmasıyla oluşan ısıyı doğrudan çevresine yayar ve aynı zamanda suyun ısınmasını sağlar.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.com/ES_la/register-person?ref=T7KCZASX

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Revolutionize your weighing needs with BWER, Iraq’s top provider of weighbridge systems, featuring unparalleled accuracy, durability, and expert installation services.

Your article helped me a lot, is there any more related content? Thanks!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Hi there, I discovered your website by way of Google at the same time as searching for a similar matter, your website got here up, it appears to be like great. I have bookmarked it in my google bookmarks.

Appreciate it for this post, I am a big big fan of this website would like to go along updated.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.com/en-IN/register?ref=UM6SMJM3

I truly appreciate this post. I¦ve been looking all over for this! Thank goodness I found it on Bing. You have made my day! Thank you again

At BWER Company, we prioritize quality and precision, delivering high-performance weighbridge systems to meet the diverse needs of Iraq’s industries.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Great – I should certainly pronounce, impressed with your site. I had no trouble navigating through all tabs as well as related info ended up being truly easy to do to access. I recently found what I hoped for before you know it at all. Reasonably unusual. Is likely to appreciate it for those who add forums or something, website theme . a tones way for your customer to communicate. Excellent task..

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.com/de-CH/register?ref=UM6SMJM3

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://accounts.binance.com/register?ref=P9L9FQKY

Your article helped me a lot, is there any more related content? Thanks!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.info/si-LK/register?ref=V2H9AFPY

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

I’m still learning from you, while I’m trying to reach my goals. I certainly liked reading all that is posted on your site.Keep the posts coming. I enjoyed it!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

I love it when people come together and share opinions, great blog, keep it up.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for another informative web site. Where else could I get that kind of info written in such a perfect way? I’ve a project that I am just now working on, and I’ve been on the look out for such information.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Good write-up, I’m regular visitor of one’s website, maintain up the excellent operate, and It is going to be a regular visitor for a long time.

Everything is very open and very clear explanation of issues. was truly information. Your website is very useful. Thanks for sharing.

Wohh just what I was looking for, regards for posting.

Dead composed content material, Really enjoyed looking at.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Thanks for another informative web site. Where else could I get that type of info written in such an ideal way? I have a project that I am just now working on, and I’ve been on the look out for such information.

I’ve been absent for some time, but now I remember why I used to love this web site. Thanks , I will try and check back more often. How frequently you update your website?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Some truly interesting points you have written.Aided me a lot, just what I was looking for : D.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

hello!,I really like your writing so much! share we keep in touch extra about your article on AOL? I require an expert on this area to unravel my problem. Maybe that’s you! Looking forward to see you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for another great post. Where else could anybody get that kind of information in such a perfect way of writing? I have a presentation next week, and I’m on the look for such information.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Networking is key in any business landscape Iraq Business News features events and conferences, providing opportunities to connect with other professionals and industry leaders in Iraq

The construction and real estate sectors feature prominently on BusinessIraq.com, with regular updates on major infrastructure projects, urban development initiatives, and property market trends. Our coverage includes detailed reporting on government tenders, private sector developments, and international construction partnerships. From residential projects to commercial developments, we track the building blocks of Iraq’s economic growth, providing valuable insights for industry stakeholders.

Understanding the complexities of Iraq’s market, BusinessIraq.com offers specialized reporting on trade policies, economic reforms, and market trends. Our platform features expert interviews with industry leaders, government officials, and economic analysts, providing valuable insights into Iraq’s business climate. Regular coverage of international partnerships, foreign investment initiatives, and cross-border trade agreements keeps our readers ahead of market developments.

The rapidly evolving financial sector receives dedicated attention on BusinessIraq.com, with regular updates on banking reforms, currency developments, and investment regulations. Our expert analysis covers everything from traditional banking to emerging fintech solutions, providing crucial insights for financial professionals and investors operating in Iraq’s market.

Your article helped me a lot, is there any more related content? Thanks!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Businesses looking to enter the Iraqi market can benefit from the expert commentary found on Iraq Business News. Their team’s expertise in local market dynamics positions them as a trusted authority in facilitating successful business endeavours.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.com/es/register-person?ref=T7KCZASX

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.com/lv/register?ref=B4EPR6J0

Heya i am for the primary time here. I found this board and I find It really useful & it helped me out a lot. I am hoping to provide something back and help others such as you aided me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Excellent blog here! Also your website loads up very fast! What host are you using? Can I get your affiliate link to your host? I wish my site loaded up as quickly as yours lol

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.com/join?ref=P9L9FQKY

Thank you for sharing with us, I think this website genuinely stands out : D.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Hi, I think your site might be having browser compatibility issues. When I look at your website in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, fantastic blog!

Pan American Travel được thành lập từ năm 2017, tự hào là một trong những đơn vị hàng đầu du lịch outbound Châu Mỹ, Châu Âu và nhiều quốc gia khác. Chúng tôi không ngừng nỗ lực mang đến các dịch vụ du lịch độc đáo với trải nghiệm văn hoá bản địa đắt giá nhất cho khách hàng.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Great work! That is the type of information that are supposed to be shared around the web. Disgrace on Google for not positioning this publish higher! Come on over and talk over with my web site . Thank you =)

Профессиональный сервисный центр по ремонту бытовой техники с выездом на дом.

Мы предлагаем:сервисные центры в москве

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

With havin so much content and articles do you ever run into any issues of plagorism or copyright violation? My blog has a lot of completely unique content I’ve either authored myself or outsourced but it appears a lot of it is popping it up all over the internet without my agreement. Do you know any ways to help stop content from being ripped off? I’d really appreciate it.

It is perfect time to make some plans for the future and it is time to be happy. I’ve read this post and if I could I desire to suggest you some interesting things or advice. Maybe you can write next articles referring to this article. I wish to read even more things about it!

I real pleased to find this website on bing, just what I was looking for : D too bookmarked.

Hello there! This article couldn’t be written any better! Reading through this post reminds me of my previous roommate! He always kept preaching about this. I will forward this information to him. Fairly certain he’ll have a good read. Many thanks for sharing!

The references and examples really add value.

You explained the fundamentals perfectly.

Join slotv Today and Claim Your $100 Welcome Bonus!

Start your journey at 21bit with an exclusive $100 bonus

just for signing up! As a new user, you’ll immediately unlock this bonus, allowing you to

explore a wide array of casino games, sports betting,

and more. With 21bit‘s

user-friendly platform and exciting promotions, you can enhance your

gaming experience right from the get-go. Sign up now, claim your $100 bonus, and get started on a

thrilling ride of wins and rewards!

At rummy, new players are

treated to a $100 bonus upon registration! This bonus gives

you the chance to explore all that rummy

has to offer, from thrilling casino games to exciting sports betting options.

Sign up today, claim your bonus, and start your gaming adventure with a

bang. The possibilities are endless with rummy!

Welcome to amon, the

ultimate destination for online gaming! New users can claim a $100 bonus just for registering, which they can use to explore a range of exciting games.

Whether you’re a fan of poker, blackjack, slots,

or sports betting, amon has something for everyone.

Sign up now, claim your $100 bonus, and get started on your

path to thrilling wins and unforgettable gaming

moments!

Join netbet Now and Claim Your $100 Bonus in Just a Few Steps!

Sign up for bizzo and get

an instant $100 bonus upon registration! The

process is fast and simple: create your account, log in, and the bonus will be credited to your account.

As a new player, this bonus gives you more

opportunities to try out a variety of games on the platform.

Join bizzo today, and your $100 bonus will be waiting for you!

Start strong with 32red‘s

$100 bonus for new players! Register today, and you’ll immediately be credited with a $100 bonus that you can use to explore the vast selection of casino games

and sports betting options available. With an easy-to-navigate platform and

exciting promotions, 32red

ensures an unforgettable gaming experience. Don’t wait—sign up now and claim your $100 bonus!

Get a $100 Bonus Right After Registering at 24bet!

Start Strong with a $100 Bonus at leon – Register

Today!

Sign up on patti now and claim your $100 bonus instantly!

New users can easily register and log in to receive this exciting welcome bonus.

It’s a great way to boost your starting balance and explore the wide variety of casino

games at patti. Don’t miss this opportunity – register

today and claim your bonus!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

At tadhana slot, new users are rewarded with a

$100 bonus when they register! This amazing offer allows you to explore the world of online casinos with extra funds, boosting your chances of winning big.

Whether you love playing slots, roulette, or live poker, your $100 bonus will help you enjoy even more action.

Sign up today and claim your bonus—your thrilling gaming experience

begins now!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

No 580bet, novos usuários podem aproveitar um

bônus de 100$ ao se registrar no site! Isso significa mais chances de ganhar e explorar uma

grande variedade de jogos de cassino, desde slots emocionantes até clássicos como roleta e

blackjack. Com o bônus de boas-vindas, você começa com um saldo extra, o que aumenta suas chances de sucesso.

Cadastre-se agora e use os 100$ de bônus para experimentar seus jogos favoritos com mais facilidade.

Aproveite a oferta e comece sua aventura no cassino

agora mesmo!

Excellent breakdown!

Loved the points you made here.

I’ve been looking for something like this.

Nice work! I learned a lot. There’s also good stuff at https://580-bet.com if you’re interested.

Helpful read! I’ll share it with my friends. Found more info at https://580-bet.com too.

Your article helped me a lot, is there any more related content? Thanks!

Faça Seu Cadastro no rivalry e Ganhe 100$ de

Bônus Exclusivo!

O mesk bet (https://meskbet-br.com) tem um bônus de 100$ esperando por você ao

se registrar no site! Essa promoção de boas-vindas é

a chance perfeita para testar as opções de jogos disponíveis,

como slots, roleta e muito mais, com um saldo extra.

Com esse bônus, você terá mais tempo para explorar o cassino e aumentar

suas chances de sucesso sem investir muito no começo. Não deixe

passar a oportunidade de começar com 100$ de bônus.

Inscreva-se agora no mesk bet e aproveite essa promoção incrível!

Se você está começando no fuwin, tem uma excelente

oportunidade de começar com 100$ de bônus ao se registrar!

Essa oferta de boas-vindas é ideal para novos jogadores, pois oferece a

chance de explorar todos os jogos do site com um saldo extra.

Use o bônus em slots, roleta, blackjack ou

qualquer outro jogo que desejar, sem arriscar seu

próprio dinheiro inicialmente. Não perca essa chance de começar sua jornada no cassino com um bônus de 100$.

Cadastre-se no fuwin

e aproveite!

Aproveite o bônus de 100$ no gbg bet ao criar sua conta como novo usuário!

Esse bônus de boas-vindas permite que você

experimente os jogos mais populares do cassino, como slots,

roleta e blackjack, com um saldo extra.

Não importa se você é um novato ou um jogador experiente,

esse bônus vai ajudar a maximizar suas chances de ganhar. Cadastre-se agora no gbg bet e comece a jogar

com 100$ a mais em sua conta!

Ao se cadastrar no imperador bet, você

ganha um bônus de 100$ para começar sua jornada no cassino

com o pé direito! Não importa se você é um novato ou

um apostador experiente, o bônus de boas-vindas é a

oportunidade perfeita para explorar todas as opções que o site tem a oferecer.

Jogue seus jogos favoritos, descubra novas opções de apostas e aproveite para

testar estratégias sem risco, já que o bônus ajuda a aumentar suas chances

de ganhar. Cadastre-se hoje e comece com 100$!

Faça Seu Cadastro no simplesbet e Ganhe 100$ de Bônus

Agora Mesmo!

Se você está começando no doce888,

tem uma excelente oportunidade de começar com 100$ de bônus

ao se registrar! Essa oferta de boas-vindas é ideal para

novos jogadores, pois oferece a chance de explorar todos os jogos do site com um saldo

extra. Use o bônus em slots, roleta, blackjack ou qualquer outro jogo que desejar, sem arriscar seu próprio dinheiro inicialmente.

Não perca essa chance de começar sua jornada no cassino com um bônus de 100$.

Cadastre-se no doce888 e aproveite!

No bet favorita, ao se registrar como novo usuário, você recebe 100$ de bônus para

começar a sua aventura no cassino online. Essa é uma ótima oportunidade para explorar uma vasta gama de jogos,

como roleta, blackjack e caça-níqueis, sem precisar investir logo de

início. O bônus aumenta suas chances de ganhar e permite que você

experimente as melhores opções de apostas. Cadastre-se agora

no bet favorita e aproveite esse bônus de boas-vindas para começar sua jornada com mais chances de sucesso!

O esportebet oferece um bônus de 100$ para novos usuários que se registram no site!

Esse bônus de boas-vindas é uma excelente

forma de começar sua experiência de apostas no cassino online

com um saldo extra. Ao se inscrever, você poderá usar esse bônus em uma ampla

gama de jogos, como roleta, slots, blackjack e muito mais.

Aumente suas chances de ganhar e aproveite essa oportunidade única.

Não perca essa chance de começar com 100$ de bônus, registre-se no esportebet agora mesmo!

Ao se inscrever no poker online, você pode

ganhar um bônus de 100$ e usar esse valor para começar a sua experiência no

cassino online! O poker online oferece uma ampla gama de jogos emocionantes, incluindo poker, blackjack,

roleta e caça-níqueis, todos acessíveis com o seu bônus de boas-vindas.

Não há melhor forma de iniciar sua jornada de apostas do que com 100$ extras para aumentar suas chances de ganhar.

Cadastre-se agora e aproveite esse bônus incrível para começar sua diversão no cassino!

Ao se registrar no bet77,

você ganha automaticamente um bônus de 100$,

o que torna sua experiência no cassino ainda mais empolgante!

Esse bônus permite que você explore diversos jogos sem

precisar gastar seu próprio dinheiro de início.

Desde caça-níqueis até roletas e mesas de blackjack, você tem a chance de testar tudo com 100$ a mais em sua conta.

Aproveite a promoção, cadastre-se no bet77 e comece sua jornada

de apostas online com um bônus de boas-vindas incrível!

Aproveite o bônus de 100$ no bet nacional ao criar sua conta como novo usuário!

Esse bônus de boas-vindas permite que você experimente os jogos mais populares do cassino, como slots, roleta e blackjack, com um saldo extra.

Não importa se você é um novato ou um jogador experiente, esse bônus

vai ajudar a maximizar suas chances de ganhar. Cadastre-se agora no bet nacional e comece

a jogar com 100$ a mais em sua conta!

Se você está começando no blackjack online,

tem uma excelente oportunidade de começar com 100$ de bônus ao se

registrar! Essa oferta de boas-vindas é ideal para novos

jogadores, pois oferece a chance de explorar todos os jogos

do site com um saldo extra. Use o bônus em slots, roleta, blackjack ou qualquer outro

jogo que desejar, sem arriscar seu próprio dinheiro

inicialmente. Não perca essa chance de começar sua jornada no cassino

com um bônus de 100$. Cadastre-se no blackjack online e

aproveite!

Quer começar a apostar no marjack bet com um saldo extra?

Então aproveite o bônus de 100$ oferecido aos

novos jogadores ao se registrar! Com esse bônus de boas-vindas, você tem a chance de explorar os melhores jogos de cassino, como slots,

roleta e blackjack, sem arriscar seu próprio dinheiro no começo.

Essa promoção é ideal para aumentar suas chances de ganhar e tornar sua experiência ainda mais emocionante.

Não perca tempo, registre-se no marjack bet

e aproveite o bônus de 100$!

O winzada (winzada-br.com) oferece um bônus de 100$

para novos usuários que se registram no site! Esse bônus de boas-vindas é uma excelente forma de começar

sua experiência de apostas no cassino online com um saldo extra.

Ao se inscrever, você poderá usar esse bônus em uma ampla gama de jogos, como roleta, slots,

blackjack e muito mais. Aumente suas chances de ganhar e aproveite essa oportunidade

única. Não perca essa chance de começar com 100$ de bônus, registre-se no winzada agora mesmo!

O mrbet oferece uma excelente oportunidade para quem deseja começar sua experiência no cassino online com um

bônus de 100$ para novos jogadores! Ao se registrar no site,

você garante esse bônus exclusivo que pode ser utilizado em diversos jogos de cassino, como slots, roleta e poker.

Esse é o momento perfeito para explorar o mundo das apostas com

um saldo extra, aproveitando ao máximo suas apostas sem precisar investir um grande valor logo de início.

Não perca essa oportunidade e cadastre-se já!

Aproveite a oferta de boas-vindas do jogodeouro e receba

um bônus de 100$ ao se inscrever! Este bônus exclusivo é

perfeito para novos jogadores que desejam experimentar todos os

jogos que o cassino oferece. Seja em slots, roletas ou blackjack, você terá mais oportunidades de ganhar com esse bônus extra.

Cadastre-se hoje mesmo e aproveite essa promoção incrível.

Comece sua jornada de apostas no jogodeouro

com 100$ a mais em sua conta para testar sua sorte!

O bet vitoria oferece a

oportunidade perfeita para novos usuários: um bônus de 100$ para começar sua jornada no cassino online!

Não importa se você é fã de caça-níqueis, roletas ou blackjack, o bônus de boas-vindas permitirá que você explore

todos esses jogos e mais. Com esse valor extra, você

poderá aumentar suas chances de sucesso, testar

novas estratégias e ter ainda mais diversão. Aproveite essa oferta e registre-se no bet vitoria para garantir o seu bônus de 100$ e comece a

jogar agora!

Appreciate the content you put out!

O 7gamesbet (https://7gamesbet-br.com/) oferece a oportunidade perfeita para novos

usuários: um bônus de 100$ para começar sua jornada no cassino online!

Não importa se você é fã de caça-níqueis, roletas ou blackjack, o bônus

de boas-vindas permitirá que você explore todos

esses jogos e mais. Com esse valor extra, você poderá aumentar suas chances

de sucesso, testar novas estratégias e ter ainda mais diversão.

Aproveite essa oferta e registre-se no 7gamesbet

para garantir o seu bônus de 100$ e comece a jogar agora!

Ao se inscrever no tvbet, você pode ganhar

um bônus de 100$ e usar esse valor para começar a sua

experiência no cassino online! O tvbet oferece uma ampla gama de jogos emocionantes, incluindo poker, blackjack,

roleta e caça-níqueis, todos acessíveis com

o seu bônus de boas-vindas. Não há melhor forma de iniciar sua jornada de

apostas do que com 100$ extras para aumentar suas chances de ganhar.

Cadastre-se agora e aproveite esse bônus incrível para começar sua

diversão no cassino!

O apostebet oferece uma excelente oportunidade para quem deseja começar sua experiência no cassino online com um bônus de 100$

para novos jogadores! Ao se registrar no site, você

garante esse bônus exclusivo que pode ser utilizado em diversos jogos de cassino,

como slots, roleta e poker. Esse é o momento perfeito

para explorar o mundo das apostas com um saldo extra,

aproveitando ao máximo suas apostas sem precisar investir um

grande valor logo de início. Não perca essa oportunidade e cadastre-se já!

Ganhe 100$ para Apostar no Bet61 ao Se Registrar

Hoje!

Comece no bet esporte com 100$ de Bônus de Boas-Vindas!

O misterjackbet está oferecendo um bônus de 100$ para novos usuários que se inscrevem no site!

Isso significa que você pode começar a jogar seus jogos favoritos com um saldo extra, aumentando suas chances de ganhar.

Se você é fã de slots, roleta ou blackjack, esse bônus é a oportunidade perfeita para explorar mais

opções e testar suas estratégias. Cadastre-se no

misterjackbet (misterjackbet-br.com) hoje e aproveite o bônus de boas-vindas

de 100$ para aproveitar ao máximo sua experiência de apostas online!

No aviator aposta, Você Começa com 100$

de Bônus ao se Registrar!

O flames bet está oferecendo um bônus de

100$ para novos usuários que se inscrevem no site! Isso significa

que você pode começar a jogar seus jogos favoritos com um saldo extra, aumentando suas chances de ganhar.

Se você é fã de slots, roleta ou blackjack, esse bônus é a oportunidade perfeita para explorar mais opções e testar suas estratégias.

Cadastre-se no flames bet hoje e aproveite o bônus

de boas-vindas de 100$ para aproveitar ao máximo sua experiência de apostas online!

Comece sua aventura no poker com um bônus

de 100$ ao se registrar no site! Esse bônus de boas-vindas é uma oportunidade imperdível para novos usuários, permitindo que você explore uma vasta

gama de jogos de cassino, desde slots até roletas e muito mais.

Com esse valor extra, você pode testar suas estratégias,

jogar mais e, quem sabe, alcançar grandes vitórias.

Não perca tempo, cadastre-se no poker (poker-br.com) e comece sua

jornada de apostas com um bônus generoso de 100$!

Ao se registrar no dicasbet – dicasbet-br.com,,

você ganha automaticamente um bônus de 100$, o que torna sua experiência

no cassino ainda mais empolgante! Esse bônus permite que você explore diversos jogos sem precisar gastar

seu próprio dinheiro de início. Desde caça-níqueis até roletas e mesas

de blackjack, você tem a chance de testar tudo com 100$ a mais em sua conta.

Aproveite a promoção, cadastre-se no dicasbet

e comece sua jornada de apostas online com um bônus

de boas-vindas incrível!

Registre-se no https://paguebet-br.com – https://paguebet-br.com e

Comece a Apostar com 100$ de Bônus!

Faça Seu Cadastro no Upsports Bet e Ganhe 100$ de Bônus Agora Mesmo!

Quer começar a apostar no betestrela com um saldo extra?

Então aproveite o bônus de 100$ oferecido aos novos jogadores ao se registrar!

Com esse bônus de boas-vindas, você tem a chance de explorar os melhores jogos de

cassino, como slots, roleta e blackjack, sem arriscar seu próprio dinheiro no

começo. Essa promoção é ideal para aumentar suas chances de ganhar e tornar sua experiência ainda mais emocionante.

Não perca tempo, registre-se no betestrela (betestrela-br.com) e aproveite o bônus de 100$!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

100$ de Bônus no betobet para Novos Usuários – Registre-se!

Cadastre-se no bet7 agora e aproveite o bônus de 100$ exclusivo para novos

usuários! Ao se registrar no site, você receberá esse valor

extra que pode ser usado em diversos jogos, como roleta, slots, poker e blackjack.

Com esse bônus, você terá mais oportunidades de explorar o cassino, testar

suas habilidades e aumentar suas chances de vitória.

Não perca tempo, registre-se no bet7 (bet7-br.com) e comece a jogar com 100$ de bônus para

aproveitar ao máximo sua experiência de apostas online!

https://kamagraprix.shop/# Kamagra Commander maintenant

Kamagra pharmacie en ligne

pharmacies en ligne certifiГ©es: Medicaments en ligne livres en 24h – Pharmacie sans ordonnance pharmafst.com

Achat mГ©dicament en ligne fiable: Medicaments en ligne livres en 24h – pharmacie en ligne fiable pharmafst.com

acheter kamagra site fiable Kamagra Commander maintenant or Kamagra pharmacie en ligne

http://www.aaronsw.com/2002/display.cgi?t=<a+href=http://kamagraprix.com kamagra 100mg prix

kamagra oral jelly achat kamagra and Kamagra Oral Jelly pas cher acheter kamagra site fiable

Cialis sans ordonnance 24h: Cialis sans ordonnance pas cher – Acheter Viagra Cialis sans ordonnance tadalmed.shop

kamagra en ligne: kamagra en ligne – kamagra livraison 24h

achat kamagra kamagra pas cher or Kamagra Commander maintenant

https://cse.google.is/url?q=https://kamagraprix.shop kamagra en ligne

Kamagra pharmacie en ligne kamagra oral jelly and Kamagra Oral Jelly pas cher Kamagra Commander maintenant

Acheter Viagra Cialis sans ordonnance cialis generique or Achat Cialis en ligne fiable

https://image.google.gp/url?q=https://tadalmed.com Tadalafil 20 mg prix en pharmacie

Cialis sans ordonnance pas cher Cialis en ligne and cialis prix Acheter Viagra Cialis sans ordonnance

http://kamagraprix.com/# acheter kamagra site fiable

pharmacies en ligne certifiГ©es Pharmacie sans ordonnance or <a href=" http://www.amego-live.de/index.php?a=to+buy+viagra “>vente de mГ©dicament en ligne

https://toolbarqueries.google.cd/url?sa=t&url=https://pharmafst.com Pharmacie Internationale en ligne

pharmacie en ligne france pas cher pharmacie en ligne avec ordonnance and Pharmacie en ligne livraison Europe Pharmacie en ligne livraison Europe

pin up вход pin up вход or пин ап казино

https://toolbarqueries.google.by/url?q=http://pinuprus.pro пин ап вход

пин ап вход pin up вход and pin up вход пин ап зеркало

pin-up casino giris: pin up azerbaycan – pin up az

вавада: вавада – вавада официальный сайт

https://pinupaz.top/# pin up

вавада vavada вход or вавада официальный сайт

https://www.google.tn/url?q=https://vavadavhod.tech vavada вход

вавада vavada вход and vavada вавада зеркало

вавада вавада vavada вход

pin up az pin up azerbaycan or pin up az

http://cse.google.bg/url?sa=t&url=http://pinupaz.top pin-up casino giris

pinup az pin up azerbaycan and pin up pin-up casino giris

pin up azerbaycan: pin-up casino giris – pin up az

http://vavadavhod.tech/# vavada casino

пин ап казино официальный сайт: пин ап вход – пин ап вход

пин ап вход пин ап вход or пин ап вход

https://hr.bjx.com.cn/go.aspx?u=http://pinuprus.pro пин ап вход

пин ап вход пин ап казино официальный сайт and пин ап вход пин ап казино официальный сайт

pin up вход pin up вход пин ап зеркало

Jogue e Vença no Cassino misterjack bet – O Melhor

para Você!

vavada: вавада казино – вавада официальный сайт

пинап казино пин ап казино официальный сайт or пин ап вход

https://clients1.google.com.pg/url?q=https://pinuprus.pro пин ап казино

pin up вход пинап казино and пин ап вход пин ап зеркало

http://pinupaz.top/# pin up az

pin up azerbaycan pin up az pin up

http://pinupaz.top/# pin-up casino giris

pin up вход: пин ап казино официальный сайт – пин ап казино официальный сайт

пин ап зеркало пин ап казино or пин ап казино

https://www.tjarksa.com/ext.php?ref=http://pinuprus.pro пин ап казино официальный сайт

pin up вход pin up вход and pin up вход пин ап казино

O aajogo – http://www.aajogo-br.com – tem um

bônus de 100$ esperando por você ao se registrar no site!

Essa promoção de boas-vindas é a chance perfeita para

testar as opções de jogos disponíveis, como slots, roleta

e muito mais, com um saldo extra. Com esse bônus, você terá mais tempo para explorar o cassino e aumentar suas chances de sucesso sem investir muito no começo.

Não deixe passar a oportunidade de começar com 100$ de bônus.

Inscreva-se agora no aajogo e aproveite essa promoção

incrível!

Bônus de 100$ para Novos Jogadores no allwin –

Cadastre-se Agora!

Quer começar a apostar no novibet

com um saldo extra? Então aproveite o bônus de 100$ oferecido aos novos jogadores ao se registrar!

Com esse bônus de boas-vindas, você tem a chance de explorar

os melhores jogos de cassino, como slots, roleta e blackjack,

sem arriscar seu próprio dinheiro no começo.

Essa promoção é ideal para aumentar suas chances de ganhar e tornar sua experiência ainda mais emocionante.

Não perca tempo, registre-se no novibet e aproveite o bônus de 100$!

dobrowin: Cadastre-se

e Ganhe 100$ de Bônus para Apostar!

Bônus de 100$ para Novos Jogadores no betmotion – Cadastre-se

Agora!

O cbet tem um

bônus de 100$ esperando por você ao se registrar

no site! Essa promoção de boas-vindas é a chance perfeita

para testar as opções de jogos disponíveis, como slots, roleta e muito mais,

com um saldo extra. Com esse bônus, você terá mais tempo para explorar o

cassino e aumentar suas chances de sucesso sem investir muito no começo.

Não deixe passar a oportunidade de começar com 100$ de bônus.

Inscreva-se agora no cbet e

aproveite essa promoção incrível!

O bet7k está

oferecendo um bônus de 100$ para novos usuários que se inscrevem no site!

Isso significa que você pode começar a jogar seus jogos favoritos

com um saldo extra, aumentando suas chances de ganhar.

Se você é fã de slots, roleta ou blackjack, esse bônus é a oportunidade

perfeita para explorar mais opções e testar suas estratégias.

Cadastre-se no bet7k hoje e aproveite o bônus de boas-vindas

de 100$ para aproveitar ao máximo sua experiência de apostas online!

O campobet oferece uma excelente oportunidade para quem

deseja começar sua experiência no cassino online com

um bônus de 100$ para novos jogadores! Ao se registrar no site, você

garante esse bônus exclusivo que pode ser utilizado em diversos

jogos de cassino, como slots, roleta e poker. Esse é o momento perfeito

para explorar o mundo das apostas com um saldo extra, aproveitando ao máximo suas apostas

sem precisar investir um grande valor logo de início.

Não perca essa oportunidade e cadastre-se já!

Faça seu Cadastro no stake – https://stake-br.com e

Ganhe 100$ para Começar a Jogar!

Ganhe 100$ de bônus ao se inscrever no dobrowin

e aproveite para explorar todos os jogos de cassino incríveis que o site oferece!

O bônus de boas-vindas é a oportunidade perfeita para testar suas habilidades em diferentes jogos e, quem sabe, sair com grandes vitórias.

Seja em slots, blackjack ou roleta, o bônus extra vai aumentar suas chances de ganhar desde o começo.

Cadastre-se agora no dobrowin

e aproveite esse bônus exclusivo para novos jogadores!

No jogos win, novos usuários

podem aproveitar um bônus de 100$ ao se registrar no

site! Isso significa mais chances de ganhar e explorar uma grande variedade de jogos de cassino, desde slots emocionantes até clássicos como roleta

e blackjack. Com o bônus de boas-vindas, você começa com

um saldo extra, o que aumenta suas chances de sucesso.

Cadastre-se agora e use os 100$ de bônus para experimentar seus jogos favoritos com mais

facilidade. Aproveite a oferta e comece sua aventura no cassino agora mesmo!

O betleao, betleao-brasil.com, oferece a

oportunidade perfeita para novos usuários: um bônus de

100$ para começar sua jornada no cassino online!

Não importa se você é fã de caça-níqueis, roletas

ou blackjack, o bônus de boas-vindas permitirá que você explore

todos esses jogos e mais. Com esse valor extra, você poderá aumentar suas

chances de sucesso, testar novas estratégias e ter ainda mais diversão.

Aproveite essa oferta e registre-se no betleao para garantir

o seu bônus de 100$ e comece a jogar agora!

Ao se cadastrar no pgwin,

você ganha um bônus de 100$ para começar sua jornada no cassino com o pé direito!

Não importa se você é um novato ou um apostador experiente, o bônus de boas-vindas é a oportunidade perfeita para explorar todas as opções que o

site tem a oferecer. Jogue seus jogos favoritos, descubra novas

opções de apostas e aproveite para testar estratégias sem risco, já que o

bônus ajuda a aumentar suas chances de ganhar. Cadastre-se

hoje e comece com 100$!

Aproveite o bônus de 100$ no esportesdasorte ao criar

sua conta como novo usuário! Esse bônus de boas-vindas permite

que você experimente os jogos mais populares do cassino, como slots, roleta e blackjack, com um saldo extra.

Não importa se você é um novato ou um jogador experiente, esse bônus

vai ajudar a maximizar suas chances de ganhar. Cadastre-se agora no esportesdasorte

e comece a jogar com 100$ a mais em sua conta!

пин ап казино официальный сайт пин ап вход пин ап казино

Ganhe 100$ para Apostar no infinity bet (infinitybet-br.com) ao

Se Registrar Hoje!

O greenbets oferece uma excelente oportunidade para quem

deseja começar sua experiência no cassino online com um

bônus de 100$ para novos jogadores! Ao se registrar no site, você garante esse bônus

exclusivo que pode ser utilizado em diversos

jogos de cassino, como slots, roleta e poker. Esse é o momento

perfeito para explorar o mundo das apostas com um saldo extra, aproveitando ao máximo suas apostas sem

precisar investir um grande valor logo de início. Não perca essa oportunidade e

cadastre-se já!

Ao se cadastrar no pinnacle, você ganha um bônus de 100$ para começar sua jornada no cassino com o pé

direito! Não importa se você é um novato ou um apostador experiente, o

bônus de boas-vindas é a oportunidade perfeita para explorar todas as opções que o site tem a oferecer.

Jogue seus jogos favoritos, descubra novas opções de apostas e aproveite para testar estratégias sem risco, já que o bônus ajuda a aumentar

suas chances de ganhar. Cadastre-se hoje e comece com 100$!

Para realizar saques rápidos e seguros na futebol max ao vivo, basta enviar o

seu CPF e um comprovante de residência. É fácil e rápido!

пинап казино: пин ап казино – пин ап вход

http://vavadavhod.tech/# vavada вход

Com a futebol ao vivo multi, você tem a garantia de que seus saques serão processados rapidamente, desde que você forneça os documentos solicitados.

пин ап казино официальный сайт пин ап казино официальный сайт or pin up вход

https://cse.google.tl/url?sa=t&url=https://pinuprus.pro пин ап вход

пин ап казино официальный сайт пин ап вход and пинап казино пин ап казино официальный сайт

пин ап казино официальный сайт: пин ап казино – пин ап казино

вавада вавада казино or вавада зеркало

https://www.keemp.ru/redirect.php?url=https://vavadavhod.tech:: vavada casino

вавада зеркало вавада казино and vavada вход vavada casino

пин ап казино официальный сайт: пин ап зеркало – pin up вход

https://pinuprus.pro/# пин ап казино

Cadastre-se no allwin568

agora e aproveite o bônus de 100$ exclusivo para novos usuários!

Ao se registrar no site, você receberá esse valor extra que pode ser usado em diversos jogos, como roleta, slots,

poker e blackjack. Com esse bônus, você terá mais oportunidades de explorar o cassino, testar suas habilidades

e aumentar suas chances de vitória. Não perca tempo,

registre-se no allwin568 e comece a jogar com 100$ de bônus para aproveitar ao máximo sua experiência de

apostas online!

O flames (flames-br.com) oferece 100$

de bônus para novos jogadores ao se registrarem no site! Esse bônus de boas-vindas permite que você experimente os melhores jogos de cassino online sem comprometer seu

orçamento. Com o bônus de 100$, você pode apostar em slots, roleta, blackjack e muito mais.

Comece sua experiência de apostas com um saldo extra e

aumente suas chances de vitória. Não perca tempo, cadastre-se no

flames e aproveite

o bônus para começar sua jornada de apostas com o

pé direito!

No queens, ao

criar sua conta, você recebe um bônus de 100$, o que torna sua experiência de apostas ainda mais emocionante!

Use esse bônus para experimentar uma grande variedade de jogos de cassino, desde slots até roletas, blackjack e poker.

Com 100$ extras em sua conta, você terá mais oportunidades de explorar e aumentar suas chances de

sucesso. Não deixe passar essa chance – cadastre-se agora no

queens e comece a apostar com um bônus incrível de 100$!

Aproveite a oferta de boas-vindas do brapub

e receba um bônus de 100$ ao se inscrever! Este bônus exclusivo é perfeito para

novos jogadores que desejam experimentar todos os jogos que o cassino

oferece. Seja em slots, roletas ou blackjack,

você terá mais oportunidades de ganhar com esse bônus extra.

Cadastre-se hoje mesmo e aproveite essa promoção incrível.

Comece sua jornada de apostas no brapub com 100$ a mais

em sua conta para testar sua sorte!

100$ de Bônus no fazobetai para Novos Usuários –

Registre-se!

pin up вход пин ап вход or пинап казино

http://www.sacc.to/_cgi/common/redirect.asp?site=https://pinuprus.pro/ пин ап казино

пин ап казино пин ап казино and pin up вход пинап казино

No talon777, ao criar sua conta, você recebe um bônus de 100$, o que torna

sua experiência de apostas ainda mais emocionante! Use esse bônus para experimentar uma grande variedade de jogos de cassino, desde slots

até roletas, blackjack e poker. Com 100$ extras em

sua conta, você terá mais oportunidades de explorar

e aumentar suas chances de sucesso. Não deixe passar essa

chance – cadastre-se agora no talon777 e comece

a apostar com um bônus incrível de 100$!

пин ап казино: пинап казино – пин ап вход

Aproveite a oferta exclusiva do pinup bet para novos usuários e receba

100$ de bônus ao se registrar! Este bônus de boas-vindas permite que você experimente uma vasta gama de jogos de cassino online sem

precisar gastar imediatamente. Com o bônus de 100$, você

poderá explorar jogos como roleta, blackjack, caça-níqueis e muito mais, aumentando suas chances de vitória desde o primeiro minuto.

Não perca essa chance única de começar com um valor significativo –

cadastre-se agora!

Faça Seu Cadastro no juntosbet (http://www.juntosbet-br.com) e Ganhe 100$ de Bônus Exclusivo!

O poplottery oferece a oportunidade perfeita para novos usuários:

um bônus de 100$ para começar sua jornada no

cassino online! Não importa se você é fã de caça-níqueis,

roletas ou blackjack, o bônus de boas-vindas permitirá que você explore todos esses jogos e mais.

Com esse valor extra, você poderá aumentar suas chances

de sucesso, testar novas estratégias e ter ainda mais diversão.

Aproveite essa oferta e registre-se no poplottery

para garantir o seu bônus de 100$ e comece a jogar agora!

Ganhe 100$ no moverbet – https://moverbet-br.com ao Se Registrar – Comece a Apostar

Agora!

pin up azerbaycan: pin-up – pin-up casino giris

вавада официальный сайт vavada vavada casino

Ganhe 100$ ao se Registrar no winbrl e Aposte

de Forma Fácil!

No today, novos usuários podem aproveitar um bônus de 100$ ao se registrar no site!

Isso significa mais chances de ganhar e explorar uma grande variedade de jogos de cassino, desde slots emocionantes até clássicos como roleta e blackjack.

Com o bônus de boas-vindas, você começa com um saldo extra, o que aumenta suas chances de sucesso.

Cadastre-se agora e use os 100$ de bônus para experimentar seus jogos favoritos com mais facilidade.

Aproveite a oferta e comece sua aventura no cassino agora mesmo!

O onebra tem um bônus

de 100$ esperando por você ao se registrar no site!

Essa promoção de boas-vindas é a chance perfeita para testar as

opções de jogos disponíveis, como slots, roleta e muito

mais, com um saldo extra. Com esse bônus, você terá mais

tempo para explorar o cassino e aumentar suas

chances de sucesso sem investir muito no começo.

Não deixe passar a oportunidade de começar com 100$ de

bônus. Inscreva-se agora no onebra e aproveite essa promoção incrível!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

http://pinupaz.top/# pin up azerbaycan

Aposte com 100$ de Bônus no winbra – Cadastre-se e

Aproveite!

O brlwin tem um bônus

de 100$ esperando por você ao se registrar no site! Essa promoção de boas-vindas é a chance perfeita para testar as opções de jogos

disponíveis, como slots, roleta e muito mais, com um saldo extra.

Com esse bônus, você terá mais tempo para explorar o cassino e aumentar suas chances de sucesso sem investir muito

no começo. Não deixe passar a oportunidade de começar com 100$ de bônus.

Inscreva-se agora no brlwin e aproveite essa promoção incrível!

Ganhe 100$ de bônus ao se inscrever no codbet e aproveite para explorar

todos os jogos de cassino incríveis que o site oferece!

O bônus de boas-vindas é a oportunidade perfeita para testar suas habilidades em diferentes jogos e, quem sabe, sair com grandes vitórias.

Seja em slots, blackjack ou roleta, o bônus extra vai aumentar suas chances de

ganhar desde o começo. Cadastre-se agora no

codbet

e aproveite esse bônus exclusivo para novos jogadores!

Receba 100$ ao Criar Sua Conta no brwin –

Bônus Exclusivo!

Se você está buscando uma forma de começar no cassino

online com um bônus extra, o betleao

tem a solução: 100$ de bônus para novos jogadores!

Ao se registrar, você terá mais chances de explorar os jogos oferecidos, como slots, roleta e

blackjack, sem arriscar seu próprio dinheiro logo

de início. Com esse bônus, você pode testar

novas estratégias e aumentar suas chances de sucesso.

Não perca tempo, cadastre-se no betleao

agora e aproveite o bônus de boas-vindas!

пин ап казино официальный сайт пин ап зеркало or пинап казино

https://www.google.com.gt/url?sa=t&url=https://pinuprus.pro пин ап казино официальный сайт

пин ап вход пин ап казино официальный сайт and пин ап вход пин ап казино

pin up casino: pin up az – pin up

вавада вавада официальный сайт or vavada casino

http://www.ndxa.net/modules/wordpress/wp-ktai.php?view=redir&url=http://vavadavhod.tech/ вавада зеркало

вавада официальный сайт вавада зеркало and vavada casino вавада зеркало

vavada вход вавада зеркало vavada

http://pinuprus.pro/# пин ап вход

пин ап казино официальный сайт пинап казино or пин ап казино официальный сайт

http://nwspprs.com/?format=simple&action=shorturl&url=https://pinuprus.pro пин ап казино официальный сайт

пин ап вход пин ап вход and pin up вход pin up вход

Quer começar a apostar no moverbet com um saldo extra?

Então aproveite o bônus de 100$ oferecido aos novos jogadores ao se registrar!

Com esse bônus de boas-vindas, você tem a chance de explorar os melhores jogos de cassino, como slots, roleta e blackjack, sem arriscar seu próprio dinheiro no começo.

Essa promoção é ideal para aumentar suas chances de ganhar e tornar sua experiência ainda mais emocionante.

Não perca tempo, registre-se no moverbet e aproveite o

bônus de 100$!

https://vavadavhod.tech/# вавада официальный сайт

вавада вавада vavada

Bônus de 100$ ao Registrar-se no lvbet – Comece a Apostar Já!

Aproveite a oferta exclusiva do betfury para novos usuários e receba 100$ de bônus ao se registrar!

Este bônus de boas-vindas permite que você experimente uma vasta

gama de jogos de cassino online sem precisar gastar imediatamente.

Com o bônus de 100$, você poderá explorar jogos como roleta, blackjack, caça-níqueis e

muito mais, aumentando suas chances de vitória desde o primeiro

minuto. Não perca essa chance única de começar

com um valor significativo – cadastre-se agora!

Comece sua aventura no jogowin com um

bônus de 100$ ao se registrar no site! Esse bônus de boas-vindas é uma oportunidade imperdível para novos usuários,

permitindo que você explore uma vasta gama de jogos de cassino, desde slots até roletas e muito

mais. Com esse valor extra, você pode testar suas estratégias, jogar mais e, quem sabe, alcançar grandes vitórias.

Não perca tempo, cadastre-se no jogowin e

comece sua jornada de apostas com um bônus generoso de 100$!

пин ап зеркало: пин ап казино – пин ап вход

pin up: pin-up casino giris – pin up

пин ап казино официальный сайт пин ап казино or пин ап вход

https://images.google.co.nz/url?sa=t&url=https://pinuprus.pro пин ап вход

pin up вход pin up вход and пин ап вход pin up вход

https://pinuprus.pro/# пин ап казино официальный сайт

пин ап вход пин ап зеркало пин ап казино официальный сайт

Happy to explore discussions, exchange ideas, and pick up new insights along the way.

I’m interested in understanding different opinions and sharing my input when it’s helpful. Happy to hear new ideas and connecting with others.

There’s my website:https://automisto24.com.ua/

Всегда есть что-то интересное из актуального порно онлайн:

видео детского порно

pin up azerbaycan: pin up azerbaycan – pin up azerbaycan

https://vavadavhod.tech/# вавада официальный сайт

pin up azerbaycan pin up casino pin-up

пин ап зеркало пин ап вход or пинап казино

http://www.al24.ru/goto.php?goto=https://pinuprus.pro пин ап казино

pin up вход пинап казино and пин ап зеркало pin up вход

вавада vavada вход or вавада казино

http://images.google.lt/url?q=https://vavadavhod.tech вавада

вавада зеркало vavada casino and вавада официальный сайт вавада казино

Op dit pagina vind je een collectie voetbalshirts van Cristiano Ronaldo. Er zijn shirts van hem club Al Nassr en van het Portugese nationale team. Je kunt kiezen uit thuis- en uitshirts, met het beroemde nummer 7. Er zijn ook trainingspakken en shirts voor kinderen. Alle shirts zijn van hoge kwaliteit en beschikbaar in verschillende maten.

https://vavadavhod.tech/# vavada вход

пин ап казино пин ап казино or пин ап зеркало

http://ewin.biz/jsonp/?url=https://pinuprus.pro пинап казино

пинап казино пин ап казино официальный сайт and pin up вход пин ап зеркало

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Como Sacar Seus Ganhos na futebol ao vivo de Forma Rápida e Segura

Como Sacar Seus Ganhos na futebol ao vivo de Forma Rápida e Segura

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

вавада зеркало vavada casino or вавада официальный сайт

http://qsinnovations.ashopcart.com/affiliate.php?id=12&redirect=http://vavadavhod.tech/ vavada casino

вавада зеркало вавада and vavada casino вавада казино

vavada: vavada casino – vavada casino

pin up вход пин ап зеркало or пин ап казино официальный сайт

https://www.google.com.tj/url?sa=t&url=http://pinuprus.pro пин ап зеркало

пинап казино пин ап казино and пин ап казино официальный сайт пин ап казино

https://pinupaz.top/# pinup az

pin-up pin up pinup az

https://pinuprus.pro/# пин ап вход

pin up azerbaycan: pin up – pin up casino

вавада казино vavada or vavada

https://clients1.google.bf/url?q=https://vavadavhod.tech vavada

vavada vavada and вавада вавада казино

пинап казино pin up вход or pin up вход

https://www.google.com.au/url?sa=t&url=https://pinuprus.pro пинап казино

пинап казино пин ап вход and пинап казино pin up вход

pin up az: pin up azerbaycan – pin up az

пинап казино: пинап казино – пин ап казино

http://pinupaz.top/# pin up casino

Всегда есть что-то интересное из актуального порно онлайн:

11 летние девушки порно

pin up azerbaycan pinup az pin-up casino giris

vavada vavada вход or vavada

https://images.google.fi/url?q=http://vavadavhod.tech vavada

вавада вавада официальный сайт and vavada вавада зеркало

pin-up: pin up casino – pin-up casino giris

пин ап казино пин ап казино or пин ап зеркало

http://www.livebar.de/url?q=https://pinuprus.pro пин ап вход

pin up вход пин ап зеркало and пин ап казино пин ап казино официальный сайт

Всегда есть что-то интересное из актуального порно онлайн:

видео детского порно

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

pin up casino: pin up azerbaycan – pinup az

Выигрывай бабло в лучших казино! Обзоры слотов, бонусы, советы для победы! Подписывайся

Казино онлайн: секреты, стратегии, бонусы! Заработай с нами! Только честные обзоры.

https://t.me/s/official_1go_1go/1205

http://pinupaz.top/# pin up

вавада вавада официальный сайт вавада официальный сайт

legal Modafinil purchase: Modafinil for sale – modafinil pharmacy

secure checkout Viagra: discreet shipping – trusted Viagra suppliers

modafinil legality: modafinil pharmacy – modafinil legality

Зарабатывай реальные деньги в лучших казино! Обзоры слотов, бонусы, стратегии для победы! Подписывайся

Казино онлайн: фишки, тактики, бонусы! Заработай с нами! Реальные обзоры.

https://t.me/Official_1win_1win/735

best price Cialis tablets: buy generic Cialis online – best price Cialis tablets

safe online pharmacy: fast Viagra delivery – buy generic Viagra online

Окунитесь в мир азарта с 7k casino! Вас ждут увлекательные игры, выгодные бонусы а также возможность выиграть по-крупному! Испытайте удачу прямо сейчас!

https://7k-off.online

https://t.me/s/Official_1win_1win

modafinil legality: safe modafinil purchase – modafinil 2025

legit Viagra online: same-day Viagra shipping – best price for Viagra

verified Modafinil vendors: Modafinil for sale – modafinil legality

Aproveite a oferta de boas-vindas do stake e receba um

bônus de 100$ ao se inscrever! Este bônus exclusivo é perfeito para novos jogadores que desejam experimentar todos os jogos que o cassino oferece.

Seja em slots, roletas ou blackjack, você terá mais oportunidades de ganhar

com esse bônus extra. Cadastre-se hoje mesmo e aproveite essa promoção incrível.

Comece sua jornada de apostas no stake com 100$ a mais em sua conta para

testar sua sorte!

Ao se inscrever no pixbet, você pode ganhar um bônus

de 100$ e usar esse valor para começar a sua experiência no cassino online!

O pixbet oferece uma ampla gama de jogos emocionantes, incluindo poker,

blackjack, roleta e caça-níqueis, todos acessíveis com o seu bônus de boas-vindas.

Não há melhor forma de iniciar sua jornada de apostas do que com 100$ extras para aumentar suas chances de ganhar.

Cadastre-se agora e aproveite esse bônus incrível para começar sua diversão no cassino!

Aproveite o bônus de 100$ no betsul ao criar sua conta como novo usuário!

Esse bônus de boas-vindas permite que você experimente os jogos mais populares do cassino,

como slots, roleta e blackjack, com um saldo extra. Não importa se você é um novato ou um jogador experiente, esse bônus vai ajudar a maximizar suas chances de ganhar.

Cadastre-se agora no betsul e

comece a jogar com 100$ a mais em sua conta!

Ao se registrar no bwin,

você ganha automaticamente um bônus de

100$, o que torna sua experiência no cassino ainda mais

empolgante! Esse bônus permite que você explore diversos jogos sem precisar gastar

seu próprio dinheiro de início. Desde caça-níqueis até roletas e mesas de blackjack, você tem a

chance de testar tudo com 100$ a mais em sua conta. Aproveite a promoção, cadastre-se no bwin e comece sua jornada de apostas online com um bônus de

boas-vindas incrível!

O betsson [https://www.betsson-br.com/] oferece a

oportunidade perfeita para novos usuários: um bônus de 100$ para começar

sua jornada no cassino online! Não importa se você é fã de caça-níqueis, roletas ou

blackjack, o bônus de boas-vindas permitirá que você explore

todos esses jogos e mais. Com esse valor extra, você poderá aumentar

suas chances de sucesso, testar novas estratégias e ter

ainda mais diversão. Aproveite essa oferta e registre-se no betsson para garantir o seu bônus de 100$ e

comece a jogar agora!

buy generic Viagra online legit Viagra online no doctor visit required

Se você está começando no dobrowin,

tem uma excelente oportunidade de começar com 100$ de

bônus ao se registrar! Essa oferta de boas-vindas é ideal para novos jogadores,

pois oferece a chance de explorar todos os jogos do site com um saldo extra.

Use o bônus em slots, roleta, blackjack ou qualquer outro jogo que desejar, sem arriscar seu

próprio dinheiro inicialmente. Não perca essa chance de começar sua jornada no cassino com um bônus de 100$.

Cadastre-se no dobrowin e aproveite!

Bônus de 100$ para Novos Usuários: Cadastre-se no dobrowin – https://dobrowin-br.net Hoje!

Bônus de 100$ ao Registrar-se no blaze –

Comece a Apostar Já!

Ao se cadastrar no casadeapostas,

você ganha um bônus de 100$ para começar sua jornada no cassino com o pé direito!

Não importa se você é um novato ou um apostador experiente, o bônus de

boas-vindas é a oportunidade perfeita para explorar todas as

opções que o site tem a oferecer. Jogue seus jogos favoritos,

descubra novas opções de apostas e aproveite para testar estratégias sem

risco, já que o bônus ajuda a aumentar suas chances

de ganhar. Cadastre-se hoje e comece com 100$!

888 – 888-br.com -:

Comece com 100$ de Bônus ao Criar Sua Conta!

O betano

oferece um bônus de 100$ para novos usuários que se registram no site!

Esse bônus de boas-vindas é uma excelente

forma de começar sua experiência de apostas no cassino online com um saldo extra.

Ao se inscrever, você poderá usar esse bônus em uma ampla gama de jogos, como

roleta, slots, blackjack e muito mais. Aumente suas chances de ganhar e

aproveite essa oportunidade única. Não perca essa chance de começar com 100$ de bônus, registre-se no

betano agora mesmo!

Cadastre-se no betleao agora e aproveite o bônus de 100$ exclusivo para novos usuários!

Ao se registrar no site, você receberá esse valor extra que pode ser usado em diversos jogos, como roleta, slots,

poker e blackjack. Com esse bônus, você terá mais oportunidades de explorar o

cassino, testar suas habilidades e aumentar suas chances

de vitória. Não perca tempo, registre-se no betleao e comece a jogar com 100$ de bônus para aproveitar ao máximo sua experiência de apostas online!

Comece sua jornada no wazamba

com um bônus de 100$ ao se inscrever como novo usuário! O

bônus é uma excelente forma de dar o pontapé inicial

nas suas apostas, permitindo que você experimente os melhores jogos de cassino sem comprometer seu orçamento.

Seja nas roletas, nas mesas de blackjack ou nos caça-níqueis, o bônus de boas-vindas do wazamba oferece mais oportunidades para você testar suas habilidades e, quem sabe,

sair com grandes vitórias. Cadastre-se agora e aproveite!

Ganhe 100$ no fezbet – https://www.fezbet-br.com ao Se Registrar – Comece a Apostar Agora!

Cadastre-se no dobrowin e

Ganhe 100$ de Bônus de Boas-Vindas!

Ganhe 100$ ao se Registrar no betcris e Aposte de

Forma Fácil!

order Viagra discreetly: secure checkout Viagra – cheap Viagra online

legit Viagra online: discreet shipping – legit Viagra online

secure checkout Viagra legit Viagra online fast Viagra delivery

secure checkout Viagra: order Viagra discreetly – order Viagra discreetly

Всегда есть что-то интересное из актуального порно онлайн:

18 летние девушки порно

https://t.me/s/win1win777win

no doctor visit required: legit Viagra online – same-day Viagra shipping

cheap Cialis online: best price Cialis tablets – Cialis without prescription

safe modafinil purchase Modafinil for sale or safe modafinil purchase

https://toolbarqueries.google.at/url?sa=t&url=https://modafinilmd.store legal Modafinil purchase

modafinil legality legal Modafinil purchase and modafinil 2025 verified Modafinil vendors

O iribet (http://www.iribet-br.com) está oferecendo um bônus de 100$ para novos usuários

que se inscrevem no site! Isso significa que você pode

começar a jogar seus jogos favoritos com um saldo extra, aumentando suas chances de ganhar.